xxx247.club hot black amateur couple sex on love seat.

twinks like unfathomable penetration.www.xxxfamousvideos.com

Project ID.

01

Cann. edenn is a Medical cannabis cultivation program.

1st Production & Processing

Site of Cann. edenn

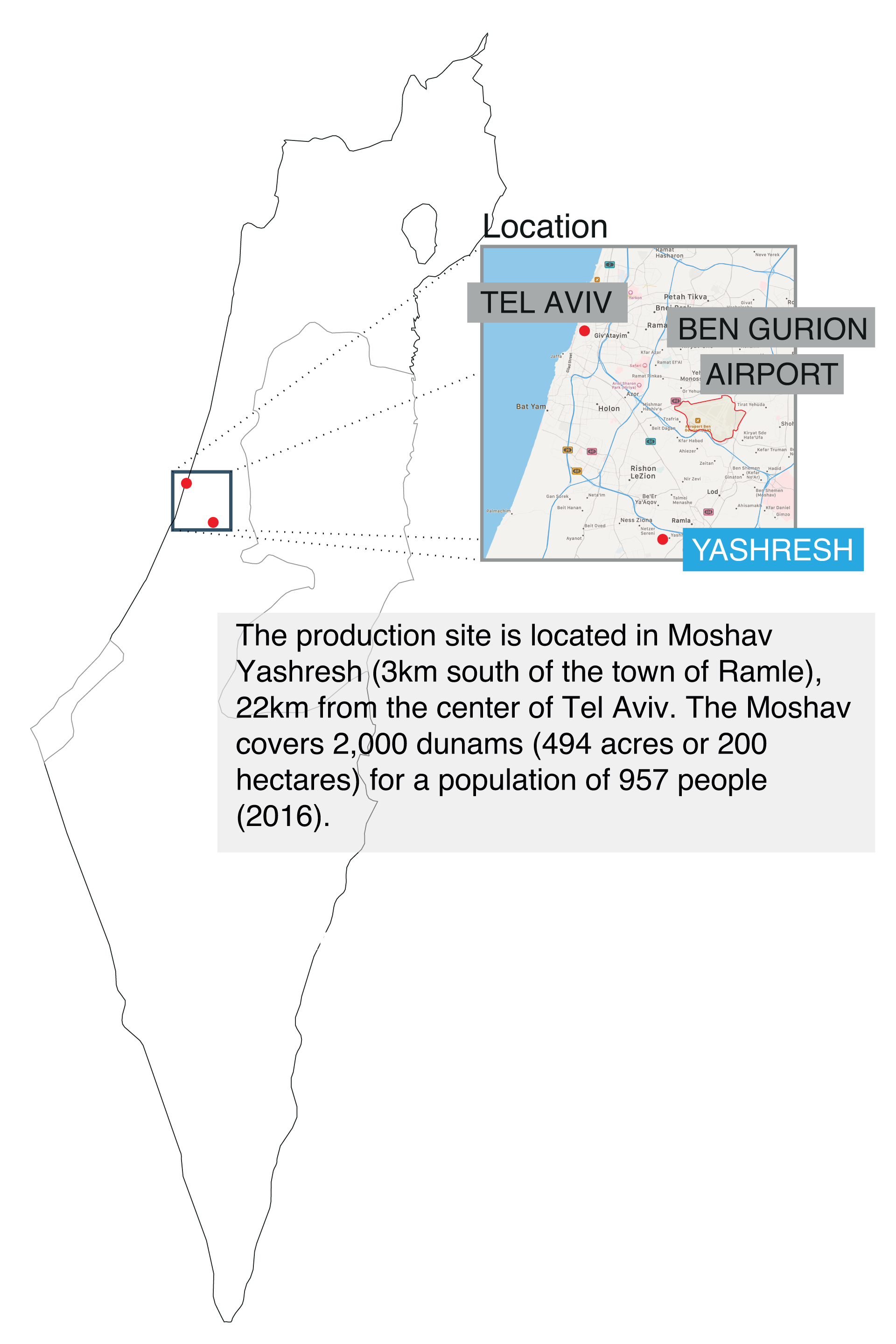

- Location

Moshav Yashresh – ISRAEL

The production site is located in Moshav Yashresh (3km south of the town of Ramle), 22km from the center of Tel Aviv. The Moshav covers 2,000 dunams (494 acres or 200 hectares) for a population of 957 people (2016)

- Size

Up to 1,100,000 square feet

- Production

Organic cannabis flower

- Farming

High Tech Greenhouses, fully automated control of the indoor climate

- Processing

Organic oil extraction processing unit

Flower Production Cycles

& Nursery

Our high-tech greenhouses provide a temperature-controlled environment for optimal production. These will enable us to carry out at least 4 production cycles per year. Production greenhouses will include a nursery area dedicated to parent plants and propagation activities. The first seeds are provided by the State of Israel.

Oil

Production

Facilities will be built and used for leaf removal, drying and processing, as well as for packaging and storage (vault) stations for flowers before shipment.

An oil extraction facility is also under construction to produce CBD oil for local distribution and export.

Focus on R&D.

02

Safety.

Providing safe and healthy products

Stability.

Providing consistent quality products over time

Efficacy.

Proving that products are effective through clinical studies

Productivity.

Increasing the productivity of greenhouses and improving the working conditions of employees

Adaptivity.

Meeting the specific needs of our customers

Anticipation.

Anticipating the evolution of the market on all our distribution channels

High Tech Greenhouses.

03

The greenhouses and agricultural structures of Cann Edenn are equipped with advanced technological solutions. They are equipped with a fully automated system, managed by control systems and used for heating, cooling, ventilation, lighting, irrigation, fertilization, CO2 enrichment and more.

Cooling.

The proposed cooling systems, based on the extraction of air via damp buffers or high-pressure misting system, significantly reduce the temperature of the greenhouse in a short time. The high-pressure misting system includes a water recycling mechanism that minimizes waste and maximizes cost savings

Light System.

Our lighting systems installed in greenhouses are designed to cope with lighting shortages and provide crops with the necessary lighting levels. Greenhouse lighting systems, which can be remotely controlled, are programmed to distribute light evenly throughout the greenhouse while saving energy.

Thermal Screens.

Another method of controlling the greenhouse temperature is to use heat shields - reflective sheets that prevent the penetration of sunlight. The screens can be opened and closed automatically according to the level of natural lighting and the required temperatures. Another type of thermal screens installed under the roof of the greenhouse is used to reduce the volume of the roof, thus allowing efficient and cost-effective heating.

Ventilation.

Ventilated greenhouses prevent the accumulation of moisture and allow the introduction of CO2. Forced ventilation systems are based on remote controlled fans that allow efficient circulation necessary for the development of the crop. The natural chimney effect derived from windows in the roof of the greenhouse also encourages efficient and cost-effective traffic

Heating.

Heating systems are installed in designated structures outside greenhouses, circulating hot air through fans and using a gas heating system. The heat generated by these systems, which can be exploited by different energy sources, is particularly high and capable of increasing the greenhouse temperature from 60 to 70 ° C.

Irrigation and Fertilization.

Our irrigation and fertilization solutions have proved their effectiveness in arid regions, including the localization of water sources, the establishment of pumping stations and pipelines, reservoirs and infrastructures, the installation of systems Advanced filtration systems, drip irrigation systems, proportional fertilization systems, water recycling systems and many other solutions that allow economical water consumption in addition to effective soil fertilization

Light Deprivation System.

This system allows to precisely control the number of hours of light and darkness; and thus control the flowering stage

Automated Control Systems.

All systems used in greenhouses are fully automated and provide full control of growing conditions 24/7. The systems are based on the most advanced technologies for measuring irrigation, humidity, temperature, lighting, etc. Data derived from these systems is transferred in real time or used for automatic activation of greenhouses.